See us at:

TECHNO-FRONTIER 2024

MOTOR TECH JAPAN

July 24-26, 2024

Tokyo Big Sight

|

A new type of electrical motor was built, tested and patented, that works in discrete steps comparable to step motors. It has many benefits, the most notable are: low price, no need for rare earth metals, few parts and high rotational resolution. USA Patent 10,468,958 was issued on November 2019.

The motor was named Skip Motor. |

新しいタイプの電気モーターをご紹介したくご連絡いたします。これは、私が開発・テストし、特許を得たモーターで、ステップモーターに相当する分散ステップで動作します。このモーターには多くの利点がありますが、中でも特筆すべき利点は、低価格であることです。レアアース金属を必要としませんし、少ない部品で高回転の分解能を有します。2019年11月に米国の特許No.10,468,958として認可されました。このモーターを、Skip Motor[スキップモーター]と名付けました。

|

|

The construction and performance of the skip motor:

|

スキップモーターの構造と性能は、以下の通りです:

|

|

|

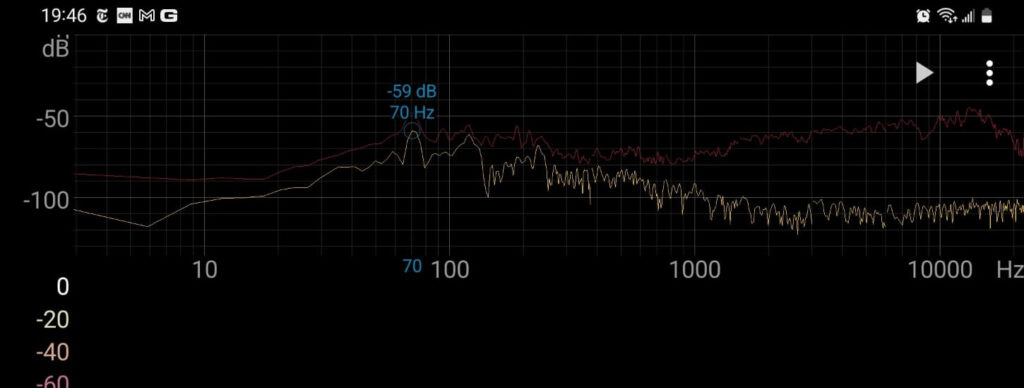

The yellow line is the background noise. The red line is the peak signal while the motor was working. The graph shows that most of the noise is above 1000 Hz, and therefore easy to shield.

Steps-Per-Revolution Calculator

Skipping Motor Comparison

|

|

DC Servomotor

|

Stepping Motor

|

Skipping Motor

|

|

Cost

|

|

|

|

|

Manufacturing cost

|

Very high

|

High

|

Very low

|

|

Controller cost

|

Very high

|

One chip

|

One chip

|

|

Requires rare earths?

|

Yes (if brush-less)

|

Yes (for locking)

|

No (both locking/free)

|

|

|

|

|

|

|

Manufacturing logistics

|

|

|

|

|

Shipment ready stock

|

Different controllers / position sensors for different resolutions

|

Different product lines for different resolutions

|

Can be assembled to achieve different skip resolutions with a stock of rotors having different gap dimensions.

|

|

Voltage flexibility

|

Pre-assembled with coils for a specific voltage

|

Pre-assembled with coils for a specific voltage

|

Drop-in coils for different voltages

|

|

|

|

|

|

|

System assembly

|

|

|

|

|

Requires fine alignment

|

Yes

|

Yes

|

No

|

|

Size / space taken

|

High

|

High

|

Low

|

|

Requires a gear for fine positioning

|

No

|

Yes (or micro-stepper drive electronics)

|

No

|

|

Needs a position sensor

for precise positioning |

Yes

|

No (Yes in high-accuracy applications)

|

Yes

|

|

|

|

|

|

|

Performance

|

|

|

|

|

Resolution

|

High

|

15º – 1.6º

|

2º – 0.1º

|

|

Lock/free after power-down

|

Always free

|

Free, or locking with a permanent magnet. A motor may be always locking OR always free

|

Yes, the same motor may be controlled just before power-down to lock or be free after power-down

|

|

Lock duration

|

—

|

Permanent

|

Tested to hold for over 3 months with 1020 soft magnetic steel rotor and stator. Need further tests.

|

|

Power consumption

|

High

|

Medium (High with micro-steps)

|

Low (need power during skips only)

|

|

Can directly produce linear motion

|

No (not counting linear motors that are different designs)

|

No

|

Yes, with 5μm-1μm resolution and no backlash

|

|

Life limited by ball bearings

|

Yes (much shorter life with brushes)

|

Yes

|

No

|

|

|

|

|

|

|

Accuracy

|

|

|

|

|

Positioning resolution

|

High

|

Low

|

High

|

|

Positioning repeatability

|

Sensor dependent

|

High

|

Sensor dependent

|

|

|

|

|

|

|

Other

|

|

|

|

|

Noise

|

Low

|

Low

|

Medium at high frequency, can be shielded

|